The Blister

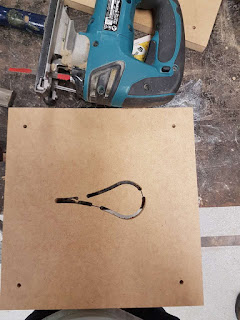

The Blister Making Step 1 - Get the template (two same patterns) CNC machine cutting by tutor & Cut the pattern inside with jigsaw power tool Step 2 - Sanding the inside part smoothly with the router power tool & filers Step 3 - Insert a piece of aluminum between two pieces template & Screw at four corners Step 4 - Hammer the aluminium part as blow a bloom Hammer the bottom part first and start around the edge. Step 5 - Keep hammering & make it more depth Then hammer to the narrow part. Step 6 - Unscrew the template and take the aluminum piece out Step 7 - Cut the outer into a shape Using scribe to measure and mark then cut with the tin snips Step 8 - Smooth the edges with filers and sand paper B